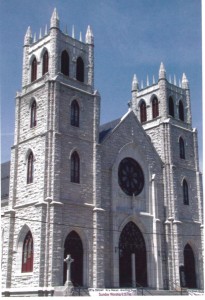

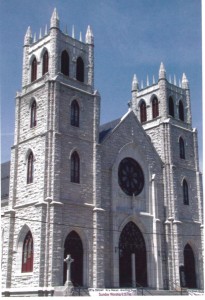

Anchoring System to be used for Structural Stabilization of Historic Church

First Lutheran Church, New Britain, CT.

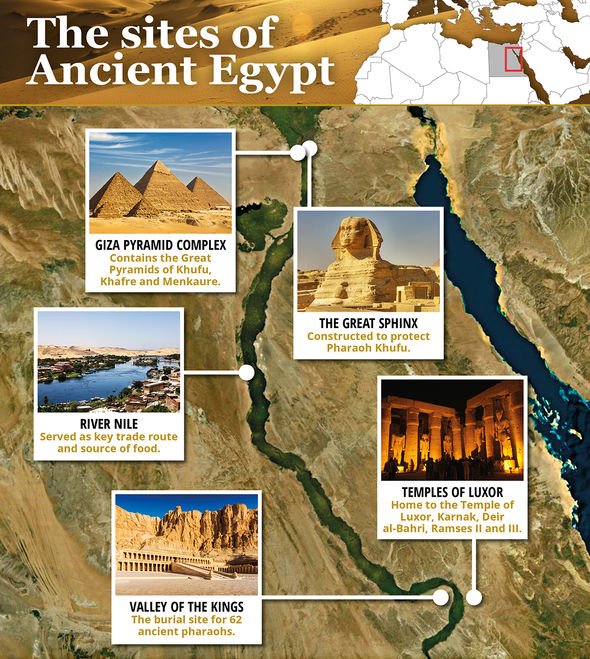

France

France Netherlands

Netherlands China

China

Most archaeologists believe the 4,500-year-old ancient monument was constructed for the Pharaoh Khufu over two decades. Among the Seven Wonders of the Ancient World, it is the only one still largely intact and is estimated to weigh approximately six million tonnes, from the 2.3 million blocks of limestone used. There have been varying theories about the Great Pyramid’s construction techniques, but the most accepted hypotheses are based on moving each of these stone blocks from a nearby quarry and lifting them into place.

But, Peter James says that is “nonsense”.

The structural engineer has spent the last 14 years working on preserving the historic buildings and temples of Egypt with his company Cintec, most recently the Step Pyramid which reopened this year. He told Express.co.uk: “If you build a house, what happens is you go to the site and put the foundations in, then they determine the shape of the house.

“They start in the four corners, they go up, then they fill in between.

“The whole building goes up in mass and it’s level. That’s exactly what they did with the Great Pyramid.

“Everyone gets pi involved, the stars and the outer angles, but it’s so simple that it’s laughable.”

Mr James, who is the author of ‘Saving the Pyramids: Twenty First Century Engineering and Egypt’s Ancient Monuments,’ explained why he believed the Egyptians were not much different from builders today.

He added: “The Great Pyramid is 230 metres long and approximately 150 metres high.

“As long as a block goes in and is the same height up, you can start on all four corners and go all the way up at the same 45 degrees.

“It’s exactly what masons do today, they make sure it’s square. As the pyramid went up the top got smaller.”

“The Egyptians believe there are 2.6 million blocks in the Great Pyramid.

“That means that if you took these from the quarry, one at a time, you would need one every six minutes to do it in 25 years. That’s absolute nonsense.”

The former Royal Navy lieutenant-commander outlined his own theory for Express.co.uk.

He said: “No builder would ever put squared blocks inside.

“If you just build the outside foundation you can fill it with much smaller blocks quicker.

“I suspect what happened is they started on the corners, went up, had ramps put inside and got to the burial chamber about 50 metres up.

“As they went up, they would have got to a point where they put support beams in which would have created gaps.

“They would have left these empty or filled them with a material that is a different density to the outside.”

Even more incredibly, the Newport-based Egyptologist says he has seen evidence of this through a new project he has recently undertaken at the Bent Pyramid.

He said: “What is more significant is when we started work on the Bent Pyramid, the Ministry of Antiquities wanted to scan it with ground-penetrating radar to make sure there were no voids inside that we might be breaching.

“If you look at them, they show the blocks up to about four metres are fairly large, after that they break up into small sections.

“This ground-penetrating radar proves they made the outer casing quite big, but inside they reverted to smaller blocks.

“It makes complete sense, nobody in those days would want to carry that many heavy stones.

“Of course they could do it in much quicker time and they would not need as many people.”

Mr James has spent his career strengthening and restoring historically significant structures all around the world, from Windsor Castle to the White House.

In ‘Saving the Pyramids,’ he puts forward a unique perspective to the structural engineering of ancient Egypt, giving his opinion on common theories surrounding the pyramids – along with new and innovative projections on their construction.

The book, which is published by University of Wales Press, is available for purchase in bookstores throughout the UK, as well as online here.

First Lutheran Church, New Britain, CT.

CINTEC American’s Blast Window Retention Anchor Systems offer a customized solutions for each application and masonry substrate to provide maximum resistance to explosions. The system process begins with an inspection of the structure by qualified personnel. The structure is then modeled to assess the most likely response and the risk inherent to the structure, determining the best reinforcement pattern. At the site, the system, made of a steel bar enclosed in a mesh fabric sleeve, is inserted into the masonry, and then connected to the frames. A non-polymer, cementitious grout then is injected into the sleeve under low pressure. The grout fuses with the mesh, expands and shapes itself around the steel to fit the space.

CINTEC American’s Blast Window Retention Anchor Systems offer a customized solutions for each application and masonry substrate to provide maximum resistance to explosions. The system process begins with an inspection of the structure by qualified personnel. The structure is then modeled to assess the most likely response and the risk inherent to the structure, determining the best reinforcement pattern. At the site, the system, made of a steel bar enclosed in a mesh fabric sleeve, is inserted into the masonry, and then connected to the frames. A non-polymer, cementitious grout then is injected into the sleeve under low pressure. The grout fuses with the mesh, expands and shapes itself around the steel to fit the space.

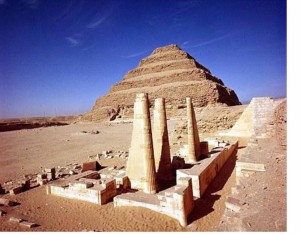

CINTEC Worldwide, a Structural masonry retrofit company, has been featured in the National Geographic documentary “Saving Egypt’s Oldest Pyramid” for their restoration of the Pyramid of Djoser.

CINTEC Worldwide, a Structural masonry retrofit company, has been featured in the National Geographic documentary “Saving Egypt’s Oldest Pyramid” for their restoration of the Pyramid of Djoser.

Cintec™ was called in by the Supreme Council of Egyptian Antiquities to prevent the collapse of the 4,600 – year-old Pyramid Djoser. The 200- foot- structure, commonly known today as the Step Pyramid, was built in the 27th Century B.C. for the burial of Pharaoh Djoser. A major earthquake in 1992 caused significant damage, resulting in the partial collapse of the burial chamber and leaving the pyramid’s central chamber in danger of collapse.

CINTEC was selected to stabilize the pyramid because of its extensive experience in preserving historical landmarks. They have cemented their reputation worldwide with projects, which included Buckingham Palace, Windsor Castle, and the White House complex, as well as countless castles and churches. In Egypt alone, CINTEC has worked on 13 historic buildings in Cairo and the Red Pyramid near Giza.

“Though each project presents a different set of challenges, CINTEC uses solid engineering principles and creative thinking to develop effective restoration solutions,” says Peter James, managing director of Cintec™ Worldwide. “We are very excited to have applied our expertise to the Step Pyramid project.”

The company used its Waterwall technology, which consists of self-inflating air-filled bags, to prevent the collapse of the damaged ceiling. To strengthen the building’s central chamber, the company used its patented anchoring and reinforcement system, designed to internally stabilize structures, while preserving their historical value and appearance.