Acetylene Isolator

The Acetylene Isolator was designed and tested to be deployed and inflated around an acetylene cylinder that has been accidentally heated and is considered unstable.

The Acetylene Isolator was designed and tested to be deployed and inflated around an acetylene cylinder that has been accidentally heated and is considered unstable.

The 335 mm PVC coated and internally reinforced Waterwall comprises of three walls and a roof section with a separate door section that is added once the main structure is in position. All the panels are fitted with pressure relief valves to avoid over filling and indicating when full of water.

The product has been tested by the Royal College of Science test range in Wiltshire United Kingdom in 2008 when acetylene bottles were heated to destruction inside a standard Waterwall unit.

The Waterwall units can be configured to cover acetylene cylinders that are standing prone, laying horizontally or against a wall.

It is recommended that the Waterwall is positioned after the heat source has been removed using the Cintec™ robot that has been especially designed for the task.

Specifications

- External Height – 2035mm/80”

- External Width – 1670mm/66”

- External Depth – 1470mm/58”

- Internal Height – 1700mm/67″

- Internal Width – 1000mm/39″

- Internal Depth – 800mm/31″

- Wall Thickness – 335mm/13”

- Water Volume – 3900 litres/1030 US Gal

- Weight Empty – 44 Kgs/97 lbs

- Weight Full – 3944 Kgs/8695 lbs

Firemote & Cylinder Isolation Unit / Remote Deployment & Firefighting

A joint venture between Cintec™ International Ltd and Ryland Engineering has produced a complimentary versatile combination of stand-alone fire fighting robot coupled with a blast mitigation product known as Waterwall.

A joint venture between Cintec™ International Ltd and Ryland Engineering has produced a complimentary versatile combination of stand-alone fire fighting robot coupled with a blast mitigation product known as Waterwall.

The partnership has produced a robotic vehicle that is small enough to enter narrow entrances such as domestic or small workshop doorways, climb steps and thresholds and manoeuvre around obstacles. With the aid of a camera and/or thermal imager the robot can attack the seat of the fire using an articulated arm that can be elevated and traversed remotely. The water connection is at the rear of the robot and it passes through the body of the robot into the articulated arm at the front. The arm has an electronically controlled valve attached to the end of the arm that can give a variety of spray effects to fight the fire.

Once the fire is under control, the robot is able to search the area for any dangerous acetylene gas bottles that may have been in or adjacent to the fire or any other industrial hazards. Should an acetylene bottle be discovered, the robot identifies the site and position and notes any obstacles that may obstruct clear access to the cylinder. It then returns to the controller to have a quick attachment jig mounted on the front and main body of the robot. Should it be necessary for the robot to return to the cylinder to clear a access area around the cylinder it will be able to using the jig as a plough. When a clear area has been formed, the robot returns to the controller for the Waterwall cylinder isolation unit. The Waterwall cylinder isolation unit has been tested to destruction at the Royal College of Science testing range at COTEC West Lavington, Salisbury Plain, England. This test report is available on request.

Once the fire is under control, the robot is able to search the area for any dangerous acetylene gas bottles that may have been in or adjacent to the fire or any other industrial hazards. Should an acetylene bottle be discovered, the robot identifies the site and position and notes any obstacles that may obstruct clear access to the cylinder. It then returns to the controller to have a quick attachment jig mounted on the front and main body of the robot. Should it be necessary for the robot to return to the cylinder to clear a access area around the cylinder it will be able to using the jig as a plough. When a clear area has been formed, the robot returns to the controller for the Waterwall cylinder isolation unit. The Waterwall cylinder isolation unit has been tested to destruction at the Royal College of Science testing range at COTEC West Lavington, Salisbury Plain, England. This test report is available on request.

The Waterwall is attached un-inflated to the front of the robot with water hose and air connections to the rear of the unit.

The controller guides the robot into the building and directly in front of the cylinder. Air is pumped into the isolator. The isolation unit is packed in such a way that it inflates to the correct profile and attitude that is needed to position it around the cylinder. When it forms its final shape the robot positions the unit to surround the cylinder on three sides. Usually, gas cylinders are attached to a wall or stand and an added door is not required. However, this can be provided if needed.

The controller guides the robot into the building and directly in front of the cylinder. Air is pumped into the isolator. The isolation unit is packed in such a way that it inflates to the correct profile and attitude that is needed to position it around the cylinder. When it forms its final shape the robot positions the unit to surround the cylinder on three sides. Usually, gas cylinders are attached to a wall or stand and an added door is not required. However, this can be provided if needed.

When the cylinder is totally encapsulated and the Waterwall is in its final position, water is pumped in displacing all the air in the bag. This is controlled using pressure relief valves positioned at the very top of the bag. When finally inflated the Waterwall surrounding the gas cylinder with 3900 litres or 1030 US gals of water which reduces the stand-off safe distance to less than five metres. The robot is then remotely detached from the unit and can continue to be deployed.

Waterwall Water Storage Units – Hexagon Water Dams – 10,000 Litre Unit

The hexagon water storage dams are designed to provide rapid storage capabilities for fire fighting appliances.

The hexagon water storage dams are designed to provide rapid storage capabilities for fire fighting appliances.

Due to the limited water storage of a fire appliance it is necessary to provide additional water to the appliance if a mains supply is not available. This storage unit allows a bowser or tanker to fill the unit and leave to refill, while the fire appliance can draw the water from the storage unit.

The Waterwall dam is able to be used even on uneven ground and gentle slopes.

Waterwall dams are bespoke designs that can be made to suit the clients requirements and can vary in size and capacity.

The Waterwall dam comes flat packed in its own valise. It is then inflated using an air pump or a compressed air supply. As soon as the dam is inflated it is ready to receive water.

Specifications:

- External Height – 1000mm/39”

- External Width – 4346mm/171”

- External Depth – 3764mm/148”

- Internal Height – 1000mm/39″

- Internal Width – 4000mm/157″

- Internal Depth – 3464mm/136″

- Wall Thickness – 150mm/6”

- Water Volume – 10,392 litres/2745 US Gal

- Weight Empty – 58 Kgs/127 lbs

- Available Sizes – 3000, 5000, 7000, 10,000 lt & Custom/792, 1320, 1849, 2641 USGal, Custom

Water Dam Deployment Instructions

Inflation

Operation

Emptying

Deflation

Repairing

Components

Fortress Flood Defence System

Initial Information

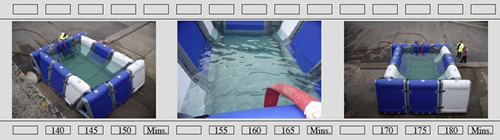

The illustrations show the first Test of the product at Maindee Fire Station on 12th March 2009. The test was achieved by forming the units into an unbroken rectangle to enable water to be introduced into the preformed enclosure that would be sufficiently water tight to enable the barriers to work successfully. The entire exercise took two and a half hours, demonstrating the speed of erection and ease of assembly. The product is very quickly dismantled and stored for future use.

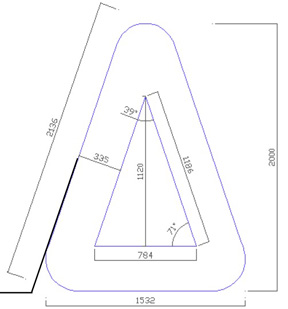

The modular system of ‘A’ frames which are inflated with air are positioned next to each other across the low lying area, the joins are sealed with PVC strips which are attached to each unit. The bottom edge is fitted with a PVC skirt which spreads in front of the units to form a seal with the ground. Once in position the units are filled with water, displacing the air from the units through pressure relief valves, which maintains the shape during filling.

Each unit measures 2000mm high x 1532 deep x 1561mm wide and holds 1,700 litres of water, which forms a solid wall of water able to withstand water to a height of 1.5mts. Each unit weighs 32kgs and can be easily transported and erected. The units can be formed into a straight wall or, using the shaped corner units, be placed completely around a building or structure, to create a dry area within.

Cintec™ International Ltd. Have extended its pneumatic and fabric technology to produce a bespoke, novel, temporary flood barrier known as Fortress.

Cintec™ International Ltd. Have extended its pneumatic and fabric technology to produce a bespoke, novel, temporary flood barrier known as Fortress.

The newly patented system is designed to create internal shear into fabric walls using internal reinforcement that allows water to form walls of the desired shape and size.

The individual wall sections come flat packed in a valise and are quickly inflated to the desired shape using an air pump. Once the walls have been erected they are joined together to form a wall similar to a castle fortress. This can be in a straight line or in the shape of a coffer dam or any other configuration that may be required.

Once in position the units are individually pumped with water, displacing the air through relief valves and providing a solid structure that is capable of withstanding water pressure to a height of 1.5mts. If additional support is required, the inner triangle section can also be air or water filled to give additional strength and support.

The construction joints are waterproofed using PVC flaps attached to the Waterwalls using velcro strips at both sides and the base of each unit, on top of ‘T’ shaped construction barriers.