The Cintec™ drill grout anchoring system is a versatile method of structural reinforcement that is tailored to meet the specific strengthening and repair requirements  of individual projects. Cintec™ reinforcement anchors are used in historical buildings, masonry bridges, monument repair, high rise buildings, retaining walls and harbour walls. And these are just a sampling of the areas a Cintec™ reinforcement anchor can be used. Cintec™ drill grout anchoring system can stabilize and strengthen an unreinforced masonry structure without the need for external and internal steel bracing.

of individual projects. Cintec™ reinforcement anchors are used in historical buildings, masonry bridges, monument repair, high rise buildings, retaining walls and harbour walls. And these are just a sampling of the areas a Cintec™ reinforcement anchor can be used. Cintec™ drill grout anchoring system can stabilize and strengthen an unreinforced masonry structure without the need for external and internal steel bracing.

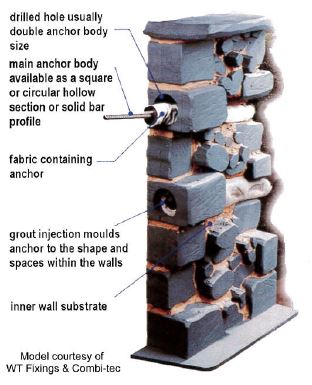

The Cintec™ drill grout anchoring system system comprises a steel section in a mesh fabric sleeve, into which a specially developed cementitious grout is injected under pressure. The flexible sleeve of woven polyester restrains the flow and expands to about twice its normal diameter, moulding itself into the shape and spaces within the walls, providing a mechanical bond.

The technical embodiment of the drill grout anchoring system is simple in that the main steel body of the anchor is completely surrounded by a fabric sock injected with a cementitious fluid grout.

The anchor is located in an over-sized drill hole joining the materials to be anchored together. The fluid grout is injected under pressure through the middle of the anchor, until it reaches the remote end. There, it passes through a series of grout flood holes into the fabric sock. The entire assembly inflates like a balloon.

The excess milk of the grout and bonding agent passes through the fabric sock, both fixing and providing a mechanical bond to the parent material. Variation in the size and shape of the individual components enable the basic method to be easily adapted to meet a designer’s requirements.