Cintec™ Reinforcing Anchoring System

The Cintec™ anchor system is recognized by civil engineers throughout the world as a highly versatile method of structural reinforcement. Its unique design features allow for adaptations that meet the specific strengthening and repair requirements individual to each project. In recent years, extensive research and development has focused upon the contribution Cintec™ anchors can and do provide in the fields of Seismic earthquake protection and seismic repair while still remaining sensitive to the original architecture.

The Cintec™ anchor system is recognized by civil engineers throughout the world as a highly versatile method of structural reinforcement. Its unique design features allow for adaptations that meet the specific strengthening and repair requirements individual to each project. In recent years, extensive research and development has focused upon the contribution Cintec™ anchors can and do provide in the fields of Seismic earthquake protection and seismic repair while still remaining sensitive to the original architecture.

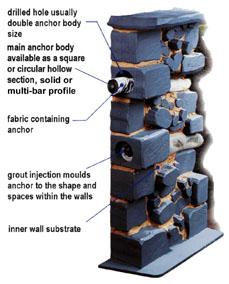

The Cintec™ anchor system comprises a steel bar enclosed in a mesh fabric sleeve into which a specially developed grout is injected under low pressure. The grout is a Portland cement based product, containing graded aggregates and other constituents which, when mixed with water, produce a pumpable cementitious grout that exhibits good strength without shrinkage. Installation is by precisely drilled holes using wet or dry diamond coring technology. The flexible sleeve of woven polyester restrains the grout flow and expands to up to twice its previous diameter moulding itself into the shapes and spaces within the walls, providing a strong mechanical bond along the entire length of the anchor without the need for unsightly patress plates on the exterior of the structure.

In brief Cintec™ anchors have the following advantages:

- Custom designed for each project

- Cementitious; sympathetic to original structure

- Age tested for durability

- Invisible when installed

- Fire Resistant

- Controlled grout flow and containment

- Quickly installed

- Approved by heritage organisations world-wide

The size and type of steel anchor, the strength of grout and the diameter of the hole can all be varied to provide the required design parameters and to provide good stiffness compatibility with the masonry. The bond strength between the grout and the masonry are usually derived from static pull out tests. We are frequently asked questions regarding seismic retrofitting and seismic earthquake protection of buildings where the Cintec™ anchor systems are being considered. Such questions include advantages and disadvantages (vis-à-vis cost and structural concerns) of Cintec™’s technology versus other options such as base isolation. What do Cintec™’s anchors do that base isolation would not? Which is better for certain building types? Soil conditions?

Seismic Earthquake Protection

The anchor installed in a masonry structure can improve seismic earthquake protection and (i) the integrity of the wall construction (ii) the wall to wall connection (iii) increase the out of plane bending strength of walls and (iv) improve the capacity of the wall/roof and wall/floor connection. Statistically there is little recorded evidence of the behaviour of the Cintec™ seismic earthquake protection anchor in an earthquake. The system is a relatively recent innovation and the benefits of the improved seismic resistance and seismic earthquake protection of the anchor are only now being appreciated.