Anchoring Principle

The Cintec™ reinforcement and anchoring system offers a remarkably versatile, proven approach using masonry anchors to internally strengthen masonry buildings and structures. The system works by pre-drilling an oversized hole in the structure and inserting a masonry anchor body surrounded by a fabric sock. A cementitious grout is injected through the middle of the masonry anchor under low pressure. It passes through a series of grout flood holes into the fabric sock, inflating the entire assembly like a balloon.

The Cintec™ reinforcement and anchoring system offers a remarkably versatile, proven approach using masonry anchors to internally strengthen masonry buildings and structures. The system works by pre-drilling an oversized hole in the structure and inserting a masonry anchor body surrounded by a fabric sock. A cementitious grout is injected through the middle of the masonry anchor under low pressure. It passes through a series of grout flood holes into the fabric sock, inflating the entire assembly like a balloon.

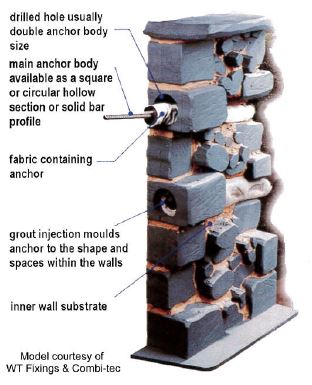

The principle of the Cintec™ masonry anchor and masonry ties is illustrated below. The stainless steel hollow section has been inserted into in situ materials in the drilled holes on either side of the cavity.

The grout has been injected under low pressure, inflating the sock throughout, but noticeably in the cavity and the hollow in the outer leaf. Milk grout has passed through the expanded sock mesh to provide a cementitious and mechanical bond to the in situ materials. Cintec™ masonry anchors and masonry ties are used in historical buildings, masonry bridges, monument repair, high rise buildings, retaining walls and harbour walls.

The Cintec™ reinforcement and anchoring system is simple and easy to use, using masonry ties and masonry anchors with fast installation and minimal cleanup. The masonry anchors and masonry ties are designed specifically for the loads and configuration of each application. Cintec™ designs generally use masonry anchors and masonry ties that are non-corrosive metal, typically stainless steel in various grades.

The masonry anchor and masonry ties are increasingly recognised as the minimal disruption answer for the upgrading of buildings, churches, monuments and historic structures. The masonry anchor and masonry ties’ unique design features allow for adaptations that meet unique project requirements while still remaining sensitive to the original structure. The fire resistant masonry is designed specifically for the loads and configuration of each application. Cintec™ designs generally usemasonry that are non-corrosive metal, typically stainless steel in various grades.

Moreover, the Cintec™ masonry anchor and masonry tie is increasingly recognised as the minimal disruption answer for the upgrading of masonry arches, taking the strain of road haulage with progressively heavier axle loadings. The masonry anchor and masonry tie system has even been applied underwater, in harbour walls and foundations, demonstrating itself to be a versatile tool, resolving the multitude of technical challenges presented to it. By working closely with all parties with an interest in historical or heritage projects, Cintec™ designs masonry anchors that offer the least intervention available for masonry structures in most cases where the alternative would be to dismantle and rebuild a masonry structure.

The Cintec™ masonry anchor offers almost limitless possibilities for strengthening, stabilising, anchoring and repairing masonry structures and other structural elements in buildings. Whether the goal is to solve an existing problem or to prevent future ones, the Cintec™ masonry anchors can prevent failure in masonry structures from many types of peril: fire, earthquakes, freeze-thaw cycles and weathering. The Cintec™masonry can help restore and maintain structural integrity of a masonry structure, with minimal intervention and generally quick installation.