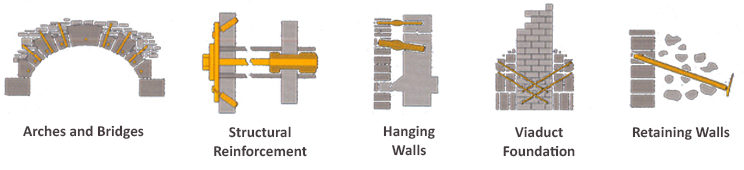

Cintec’s Drill Grout Anchoring System

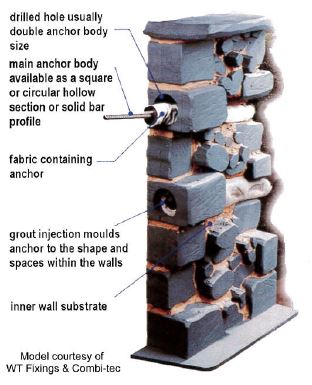

The Cintec™ drill grout anchoring system offers a remarkably versatile, proven approach to internally strengthen masonry buildings and structures. The drill grout anchoring system works by pre-drilling an oversized hole in the structure and inserting an anchor body surrounded by a fabric sock. A cementitious grout is injected through the middle of the anchor under low pressure. It passes through a series of grout flood holes into the fabric sock, inflating the entire assembly like a balloon.

THE ANCHOR

The Cintec drill grout anchoring system is a versatile method of structural reinforcement tailored to meet the specific strengthening and repair requirements of individual projects. From historical buildings and monuments to bridges, high-rise blocks and harbor walls, Cintec’s drill grout anchoring system has the worldwide reputation for resolving the technical challenges of structural preservation, whilst remaining sensitive to the original architecture. The drill grout anchoring system is designed specifically for the loads and configuration of each application. Cintec™ designs generally use drill grout anchoring systems that are non-corrosive metal, typically stainless steel in various grades.

THE SOCK

The Cintec drill grout anchoring system comprises a steel bar enclosed in a mesh fabric sleeve into which a specially developed grout is injected under low pressure. The Cintec drill grout anchoring system provides a highly versatile method of internal structural reinforcement that is tailored to meet the specific requirements of each parapet wall. The flexible sleeve of the woven polyester reinforcement system restrains the flow and molds the drill grout anchoring system into the shapes and spaces within the walls, providing a strong mechanical bond. The mesh of the reinforcement system sock is designed to contain the aggregates of the mixed grout while still allowing the cement enriched water to pass through the drill grout anchoring system’s sock both sizing and bonding the substrate.

THE GROUT

The drill grout anchoring System’s Presstec grout is a one component mix, which has the same characteristics as Portland Cement, with graded aggregates and other constituents which, when mixed with water, produce a pump-able reinforcement system grout that exhibits good strength with no shrinkage. The drill grout anchoring’s system grout is independently checked both during manufacture and before final despatch.

INSTALLATION

The Cintec drill grout anchoring system installation is through drilled holes produced by wet or dry diamond coring technology. The flexible sleeve of woven polyester in the drill grout anchoring system’s restrains the grout flow and expands up to twice its previous diameter, moulding itself into the shapes and spaces within the walls to provide a strong mechanical bond along the entire length of the anchor system. This will often dispense with the need for patress plates on the exterior of the structure.