Masonry Arch & Bridge Strengthening About the Archtec System

Archtec provides a unique bridge reinforcement system. This complete diagnostic, design and installation service, using state-of-the-art technology and drilling methods, is specially designed to strengthen masonry arch bridges internally—while preserving historical value.

Archtec’s novel system of internal strengthening involves inserting and grouting stainless steel reinforcing bars into the masonry. The use of stainless steel and a high-performance grout enhance durability. The special component in the system is the expandable fabric ‘sock’ that contains the bars and grout, protecting the surrounding masonry from being displaced or otherwise damaged by the grouting pressure of 3 to 4 bars (35/55 psi). During inflation, the sock deforms and the grout fills in the cavities in the masonry to develop a mechanical bond. The sock also permits sufficient leakage of grout milk through the fabric to form a cementitious bond with the masonry. The efficacy of this connection is evaluated by pull-out tests.

The reinforcement is positioned in the arch barrel in a longitudinal direction and tangential to the curvature. The strength of individual bridges is accurately calculated both before and after reinforcement. Numbers and precise disposition of the bars are confirmed by advanced numerical analysis using ELFEN, a non-linear discrete element program. This enables the complex composite behaviour of the reinforced masonry to be predicted and allows accurate simulation of its response to permanent and live loads.

Archtec’s confidence in the method of analysis arises from verification by full-scale tests of both strengthened and unstrengthened arches to collapse by the Transport Research Laboratory.

THE TEST

Model arch bridge constructed in brick and based on an original bridge in the UK. The arch barrel is composed of 3 brick rings, each separated by a layer of sand; there are no spandrel walls and no road surface. The test rig had steel formers to contain the fill at the edges.

The failure of the laboratory model was 20 tonnes. Following the highly accurate installation of Cintec™ anchors, the load failure point was raised to 41 tonnes. The first hinge formed at 28 tonnes; the reinforcement prevented its formation under the load line.

During loading to collapse only the bottom ring of bricks fell away; the reinforcement anchors were exposed and clearly indicated a retained load-bearing capacity.

THE RESULTS

Load Test to Failure:

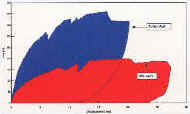

Before reinforcement, the maximum load was 20 tonnes (44,800 lbs). After the insertion of Cintec™ anchors, the maximum value was increased to 41 tonnes (91,840 lbs)—a factor of 2.05.

See table

The TRL Test: A graphical comparison between the TRL unstrengthened arch and the Archtec reinforced arch.

THE CONCLUSIONS

A bridge with a tested un-reinforced load capacity of 20 tonnes (44,800 lbs) can be upgraded to over double that capacity through the precise insertion of Cintec™ anchors. It is easy to install, causes minimum disruption to users and internal services, it is cost effective (a fraction the cost of a bridge saddle). It is invisible method of strengthening and repair.

* A complete diagnostic, design and installation service utilising state-of-the-art technology and drilling methods.

* Strengthening parameters verified by testing at TRL.